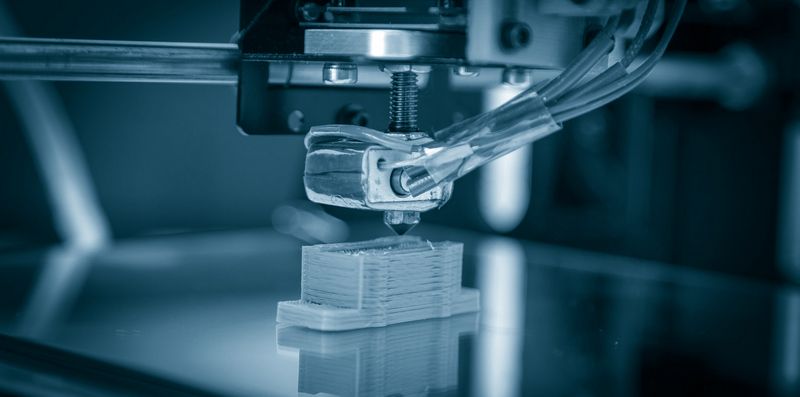

The Role of 3D Printing in Modern Auto Body Repair

In the world of auto body repair, 3D printing technology has emerged as a game-changer. With its ability to create intricate and precise parts, 3D printing is revolutionizing the way auto body repairs are carried out.

Traditionally, auto body repairs required sourcing and ordering specific parts from manufacturers, which often led to delays and increased costs. However, with 3D printing, the role of manufacturing is shifted directly to the repair shop. This means that repairs can be carried out quicker and more efficiently, reducing downtime for the customer.

One of the key advantages of 3D printing in auto body repair is its ability to create custom parts. Whether it’s a unique panel shape or a rare vintage part, 3D printers can reproduce them with ease. This eliminates the need to hunt down rare parts or compromise on the overall aesthetics of the vehicle.

Not only does 3D printing offer a cost-effective solution for auto body repair, but it also plays a significant role in reducing waste. With traditional methods, excess material is often discarded. However, 3D printing allows for precise calculations, resulting in minimal waste production.

The impact of 3D printing on auto body repair is undeniable. With its ability to create custom parts, reduce costs, and minimize waste, this technology is shaping the future of the industry. Embrace the power of 3D printing and experience a revolution in auto body repair.

Benefits of 3D Printing in Auto Body Repair

Modern technology has revolutionized the role of 3D printing in auto body repair. This innovative technique offers numerous benefits that can significantly improve the efficiency and effectiveness of repairing auto body damage.

One of the major benefits of 3D printing in auto body repair is the ability to create highly precise and customized parts. With traditional repair methods, finding and sourcing the exact part for a specific make and model can be time-consuming and costly. However, 3D printing allows for the precise replication of even the most complex auto body parts, ensuring a perfect fit every time.

Another advantage of 3D printing in auto body repair is the reduction in repair time. Traditional repair methods often require waiting for parts to be shipped or manufactured, resulting in lengthy repair times. With 3D printing, parts can be created on-demand, eliminating the need for waiting and reducing the overall repair time.

Additionally, 3D printing offers cost-saving benefits in auto body repair. Traditional repair methods may require expensive tooling, molds, or specialized equipment for specific repairs. With 3D printing, these costs can be significantly reduced, as the technology only requires a digital file and the materials needed to create the part.

Furthermore, 3D printing allows for increased creativity and design flexibility in auto body repair. The technology enables designers and technicians to experiment with different shapes, forms, and structures, ultimately leading to improved designs and enhanced aesthetics.

In conclusion, the benefits of 3D printing in auto body repair are substantial. It offers precise and customized parts, reduces repair time, saves costs, and increases design flexibility. Incorporating 3D printing into auto body repair paves the way for a more efficient, cost-effective, and visually appealing repair process.

Enhanced Precision and Accuracy

With the advent of 3D printing technology, the role of precision and accuracy in auto body repair has been revolutionized.

Gone are the days when repair technicians had to rely solely on their skills and experience to restore a damaged body to its original condition. Now, with the power of 3D printing, they have access to precise and accurate tools that enable them to achieve results that were previously unimaginable.

3D printing plays a vital role in the modern auto body repair industry by providing the means to create custom parts and components with an unparalleled level of precision.

Using advanced software and design tools, repair technicians can create digital models of damaged body parts and send them to a 3D printer. The printer then builds these parts layer by layer, with a level of precision that cannot be matched by traditional manufacturing methods. This means that the final parts fit perfectly into the body, ensuring a seamless repair job.

Furthermore, 3D printing allows for the production of complex geometries and intricate designs that would be impossible to achieve with conventional manufacturing techniques.

Whether it is a unique shape or a part with intricate details, 3D printing can reproduce it with unmatched accuracy. This not only enhances the aesthetic appeal of the repaired body but also ensures its structural integrity and functionality.

The precision and accuracy offered by 3D printing in auto body repair are game-changers, pushing the boundaries of what is possible and enabling technicians to deliver superior results.

As this technology continues to evolve and improve, we can only expect even greater advancements in the field of auto body repair.

Reduced Repair Time

Thanks to the modern advancements in 3D printing technology, the role of auto body repair has been transformed. One of the major benefits of using 3D printing in the repair process is the significant reduction of repair time.

Traditionally, auto body repairs could take days, if not weeks, to complete. However, with the introduction of 3D printing, repair time has been dramatically reduced. This is because 3D printers can quickly produce the necessary replacement parts or components with precision and accuracy.

By using a 3D printer, mechanics and technicians no longer have to wait for parts to be ordered and delivered, saving valuable time in the repair process. This means that vehicles can be back on the road sooner, minimizing downtime for both individuals and businesses.

The reduced repair time provided by 3D printing also translates to cost savings. With shorter repair times, labor costs are minimized, and customers can save money on rental cars or alternative transportation during the repair period.

Overall, the revolutionary impact of 3D printing on auto body repair extends beyond its ability to create custom parts. The reduced repair time made possible by 3D printing technology allows for quicker, more efficient repairs, benefiting both customers and businesses alike.

Cost Savings

One of the major benefits of adopting modern 3D printing technology in the auto body repair industry is the significant cost savings it offers. Traditional methods of repairing auto body damage can be expensive and time-consuming. Manual labor, sourcing of materials, and high equipment costs can quickly add up, leading to financial strain for both repair shops and customers.

With the introduction of 3D printing, the role of repairing auto body damage has drastically changed. By using digital models and advanced materials, 3D printing allows for precise and efficient repairs. This eliminates the need for costly manual labor and reduces the number of materials required for the repair process.

Furthermore, 3D printing enables repair shops to produce parts and components in-house, saving them the time and expense of outsourcing to third-party suppliers. The ability to create custom, on-demand parts results in significant cost savings, as there is no longer a need to carry a large inventory of pre-made parts.

The cost savings provided by 3D printing in auto body repair extends to the customers as well. With reduced repair costs, customers can save money on their overall repair bill. Additionally, faster repair times, made possible by the efficiency of 3D printing, mean less downtime for the customer and quicker turnaround for their vehicles.

In conclusion, 3D printing has revolutionized the auto body repair industry by providing significant cost savings. Repair shops can reduce labor, material, and inventory costs, while customers benefit from lower repair bills and faster turnaround times. As 3D printing continues to advance, its role in auto body repair will only become more prominent, offering even greater cost savings in the future.

Increased Accessibility to Replacement Parts

With the advent of modern technology, the auto industry has witnessed a revolution in the way replacement parts are obtained. 3D printing, with its groundbreaking capabilities, has played a pivotal role in making replacement parts more accessible than ever before.

Traditionally, getting replacement parts for auto body repairs could be a time-consuming and expensive process. It often involved ordering from manufacturers or searching through salvage yards for usable components. However, 3D printing has changed this landscape entirely.

By harnessing the power of 3D printing, auto body repair professionals now have the ability to recreate custom replacement parts with precision and efficiency. This groundbreaking technology allows them to reproduce intricate components that may no longer be readily available or out of production.

The beauty of 3D printing lies in its flexibility. Auto body repair technicians can use 3D modeling software to design and create any part they need, regardless of its complexity. This eliminates the reliance on specific manufacturers or suppliers, giving repair shops greater autonomy and access to a wider range of replacement parts.

Furthermore, 3D printing opens up possibilities for innovation and improvement in auto body repair processes. With the ability to customize replacement parts, technicians can enhance the overall performance and aesthetics of repaired vehicles. This not only ensures a seamless fit but also contributes to the longevity and quality of the repairs.

In conclusion, the revolutionary impact of 3D printing on auto body repair extends to increased accessibility to replacement parts. By leveraging this modern technology, repair shops can overcome the limitations of traditional sourcing methods and provide superior solutions to their customers.

Improved Aesthetics and Customization Options

3D printing technology has revolutionized the way modern auto body repair is done. Not only does it streamline the repair process, but it also offers improved aesthetics and customization options.

Gone are the days when fixing a damaged auto body meant compromising its original appearance. With 3D printing, repairs can be done with precision and accuracy, ensuring that the vehicle maintains its sleek and stylish look.

Furthermore, 3D printing allows for a wide range of customization options. Whether it’s adding unique design elements or personalizing the vehicle to reflect the owner’s individuality, the possibilities are endless. Auto body repair technicians can now bring their clients’ ideas to life and create truly one-of-a-kind vehicles.

The role of 3D printing in auto body repair cannot be overstated. It has not only improved the efficiency and accuracy of repairs but has also opened up a whole new world of possibilities for customization. As technology continues to advance, we can only expect further innovations and improvements in the field of auto body repair.

Less Waste and Environmental Impact

One of the key benefits of 3D printing in the modern auto body repair industry is its significant reduction in waste and environmental impact. Traditional repair methods often involve replacing entire body parts, resulting in a large amount of waste material. With 3D printing, only the damaged area needs to be repaired, minimizing waste and saving resources.

Furthermore, the use of 3D printing technology allows for the precise manufacturing of auto body parts, resulting in a perfect fit and reducing the need for additional modifications or adjustments. This precision not only improves the overall quality of repair work but also ensures that the repaired vehicle meets safety standards and regulations.

Additionally, 3D printing enables the use of eco-friendly materials, such as biodegradable plastics or recycled materials. This further reduces the environmental impact of auto body repairs by minimizing the use of non-renewable resources and reducing carbon emissions.

By utilizing 3D printing technology in the auto body repair process, the industry can play a significant role in reducing the environmental impact of automotive maintenance and repair. The combination of less waste, precise manufacturing, and the use of eco-friendly materials makes 3D printing an innovative and sustainable solution for modern auto body repair needs.

Challenges and Limitations of 3D Printing in Auto Body Repair

While 3D printing has certainly revolutionized the auto body repair industry, it is not without its challenges and limitations.

1. Material Limitations: One of the main challenges of 3D printing in auto body repair is the limited range of materials available for printing. While there are many different types of plastics that can be used, finding materials that can withstand the stress and strain of being part of a modern auto body is a challenge.

2. Structural Integrity: Another challenge is maintaining the structural integrity of the printed parts. Auto bodies need to withstand various external forces, such as impacts and vibrations. Ensuring that 3D printed parts have the necessary strength and durability to handle these forces is crucial.

3. Precision and Accuracy: Achieving the level of precision and accuracy required for auto body repair is also a challenge. Small errors or imperfections in the printed parts can affect their fit and function, leading to compromised repairs and potential safety issues.

4. Time and Cost: The time and cost involved in 3D printing can also be a limitation. While the technology has become more accessible and affordable over the years, it still requires specialized equipment and expertise. Additionally, printing larger auto body parts can be time-consuming, resulting in longer repair times for customers.

5. Regulatory and Certification: The adoption of 3D printing in auto body repair is also hindered by regulatory and certification requirements. Ensuring that the printed parts meet safety and quality standards set by regulatory bodies can be a complex process.

In conclusion, while 3D printing has the potential to revolutionize auto body repair, it is currently facing challenges and limitations in terms of materials, structural integrity, precision, time, cost, and regulatory compliance. These challenges need to be addressed for widespread adoption and integration of 3D printing in the auto body repair industry.

Integration of 3D Printing in Auto Body Repair Industry

The modern auto body repair industry heavily relies on advanced technologies to improve efficiency and deliver high-quality results. One of the most revolutionary technologies that has transformed the industry is 3D printing.

With the integration of 3D printing, auto body repair professionals now have access to innovative tools and techniques that streamline the repair process and ensure accurate and precise repairs. 3D printing allows for the creation of custom-made replacement parts that fit seamlessly into the damaged area, reducing the need for costly and time-consuming manual repairs.

By utilizing 3D printing technology, auto body repair shops can significantly reduce repair times and eliminate the reliance on traditional supply chains. Instead of waiting for parts to be shipped, they can simply print the required components on-site, speeding up the repair process and minimizing downtime for customers.

In addition to improving efficiency, 3D printing also plays a crucial role in enhancing the overall quality of auto body repairs. The ability to create intricate and complex parts with precision means that damaged areas can be restored to their original condition, maintaining the structural integrity and aesthetics of the vehicle.

Moreover, 3D printing enables auto body repair professionals to experiment with innovative materials and design solutions that not only strengthen the repaired areas but also improve the overall durability and longevity of the vehicles. This opens up new possibilities for creating stronger and safer vehicles, ensuring customer satisfaction and loyalty.

In conclusion, the integration of 3D printing in the auto body repair industry has revolutionized the way repairs are conducted. It has allowed for more efficient, accurate, and high-quality repairs, enabling auto body repair professionals to deliver outstanding results. As technology continues to advance, the role of 3D printing in the industry will only continue to expand, shaping the future of auto body repair.

Future Outlook for 3D Printing in Auto Body Repair

As the world becomes more reliant on modern technology, the role of 3D printing in auto body repair is only set to grow in prominence. With its ability to create intricate and precise 3D models, 3D printing is revolutionizing the way auto body repairs are conducted.

One of the key advantages of 3D printing in auto body repair is the ability to quickly and accurately manufacture replacement parts. Traditionally, when a part is damaged or worn out, it can take a considerable amount of time to source a suitable replacement. However, with 3D printing, the process of creating and producing a new part can be significantly streamlined, reducing repair times and improving customer satisfaction.

Another area where 3D printing is set to have a major impact is in the customization of auto body parts. With 3D printing, it is now possible to create unique and personalized designs that perfectly match the aesthetic preferences of each individual customer. This level of customization was once unimaginable, but thanks to 3D printing, it is now a reality.

Looking towards the future, the potential for 3D printing in auto body repair is immense. As technology continues to advance, we can expect to see even greater advancements in the capabilities of 3D printing. From the creation of more durable and lightweight materials to the ability to print entire auto bodies, the possibilities are truly endless.

| Reduces repair times and improves customer satisfaction |

| Enables customization and personalization of auto body parts |

| Potential for advancements in materials and printing processes |

| Possibility of printing entire auto bodies |

With 3D printing, the future of auto body repair is bright. The ability to quickly and accurately produce replacement parts, combined with the potential for customization and advancements in materials, will undoubtedly reshape the industry. Embracing the revolutionary impact of 3D printing is crucial for staying at the forefront of auto body repair in the modern world.

Question-answer:

What is 3D printing?

3D printing is a manufacturing process where a three-dimensional object is created by laying down layers of material, typically plastic or metal, based on a digital model.

How does 3D printing impact auto body repair?

3D printing has revolutionized auto body repair by allowing technicians to quickly and cost-effectively create replacement parts. This eliminates the need to order expensive parts from manufacturers or wait for them to be shipped.

What are the benefits of using 3D printing in auto body repair?

Using 3D printing in auto body repair offers several benefits. It allows for faster repairs, reduces costs, and enables technicians to create custom parts that may not be readily available.

Are there any limitations to 3D printing in auto body repair?

While 3D printing has many advantages, there are some limitations. The size of the printer may restrict the size of the parts that can be printed, and the materials used may not be as durable as traditional materials.

Where can I find more information about the impact of 3D printing on auto body repair?

You can find more information about the impact of 3D printing on auto body repair by conducting a search online or by reading industry publications and journals.